High temperature waste incinerators and high-temperature sludge treatment (850 to 1000°C) produce concentrated flue gases that are highly charged with Sulphur Oxides (SOx), Chloric Acids (HCL), Hydrofluoric Acids (HF), Dioxins/Furans (PCDD/PCDF) and Heavy Metals. We therefore offer injection of several reagents, in powder form, according to our customer’s needs in order to eliminate, by agglomerating to these pollutants. This treatment method can be applied to other areas than waste incinerators.

SCCM ALP by its history, ALP PROCESS is a reference for the number of smoke treatments. They are referenced by the world leaders in smoke treatment.

In order to reduce the level of sulphur oxides, hydrochloric and hydrofluoric acids we inject powdered reagents into the flue gas ducts upstream of the bag filter. We can use several products:

- Sodium bicarbonate (NaHCO3) is more efficient on sulphur oxides

- Slaked lime (Ca(HO)3) is more suitable for hydrochloric acids

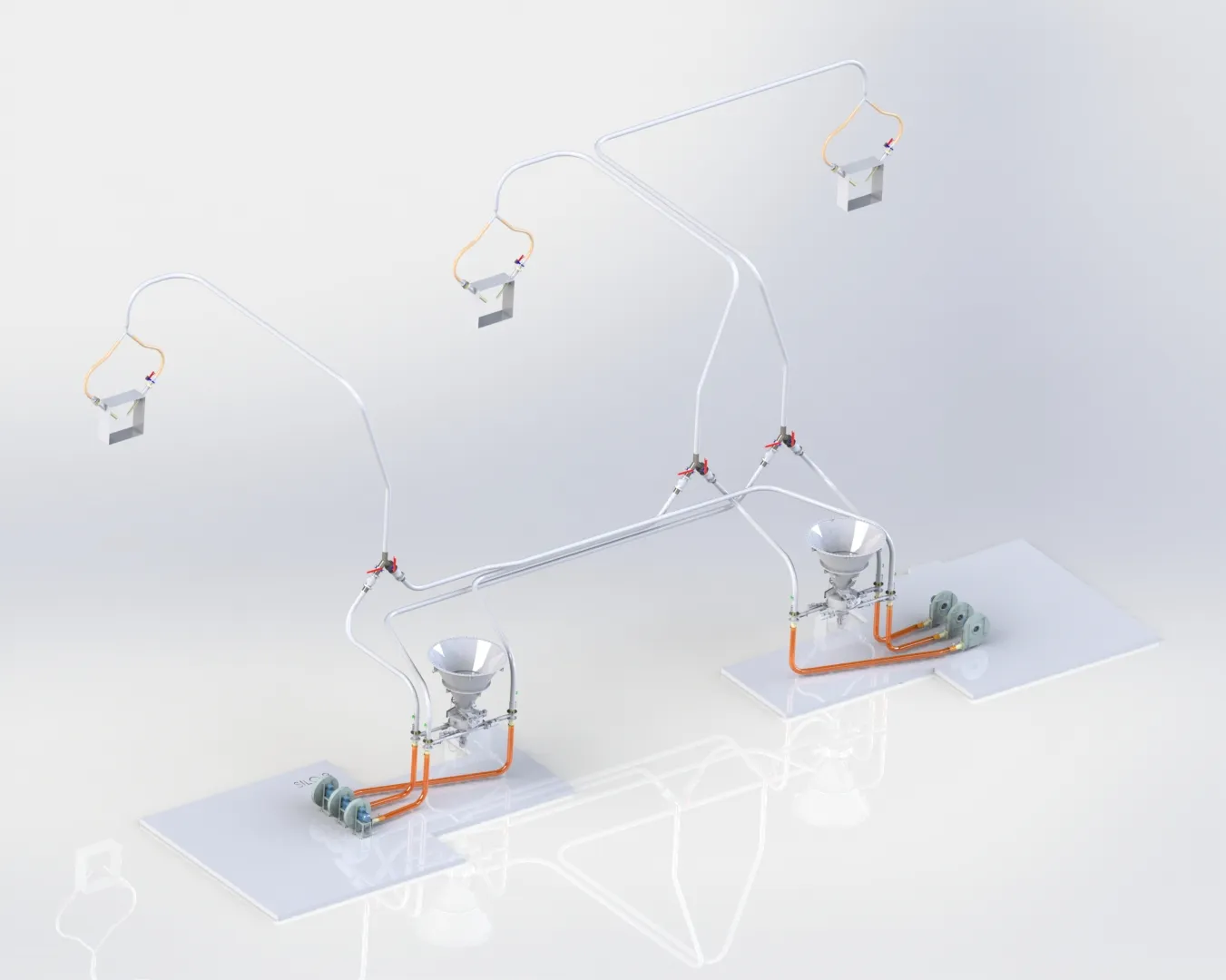

We propose complete sets :

- Storage (Silo or Big Bag)

- Extractor (devourer)

- Grinding

- Dosing (Spiral or auger)

- Pneumatic transport and injection directly into ducts thanks to our injectors

A flow range from 0.05 m3/h up to 12 m3/h with precise dosing. Possibility to feed up to 4 lines with a single silo. Dosage regulation is based on the data received from the fume analyzer. This system can be installed on a new treatment or as a complement to an existing treatment that no longer meets the standards or is subject to pollution peaks.

Submit your project

SCCM ALP Achievements

VEOLIA

Product: Pre-ground sodium bicarbonate SB/03 from Solvay

Issue: Smoke treatment with pre-crushed BICAR

Solution: Replacement of a semi-wet treatment (milk of lime) by a dry treatment with pre-crushed bicar. Cleaning of the 2 existing silos and modification of the outlet cones in order to use them for the pre-crushed sodium bicarbonate. Installation of an anti-bridging device and 3 outlet screws on each silo. Flow rate: 40 to 800 kg/h per screw. Injection made by pneumatic transport using a fan and polyurethane piping.

Applications: Incinerator SMEDAR (Rouen)

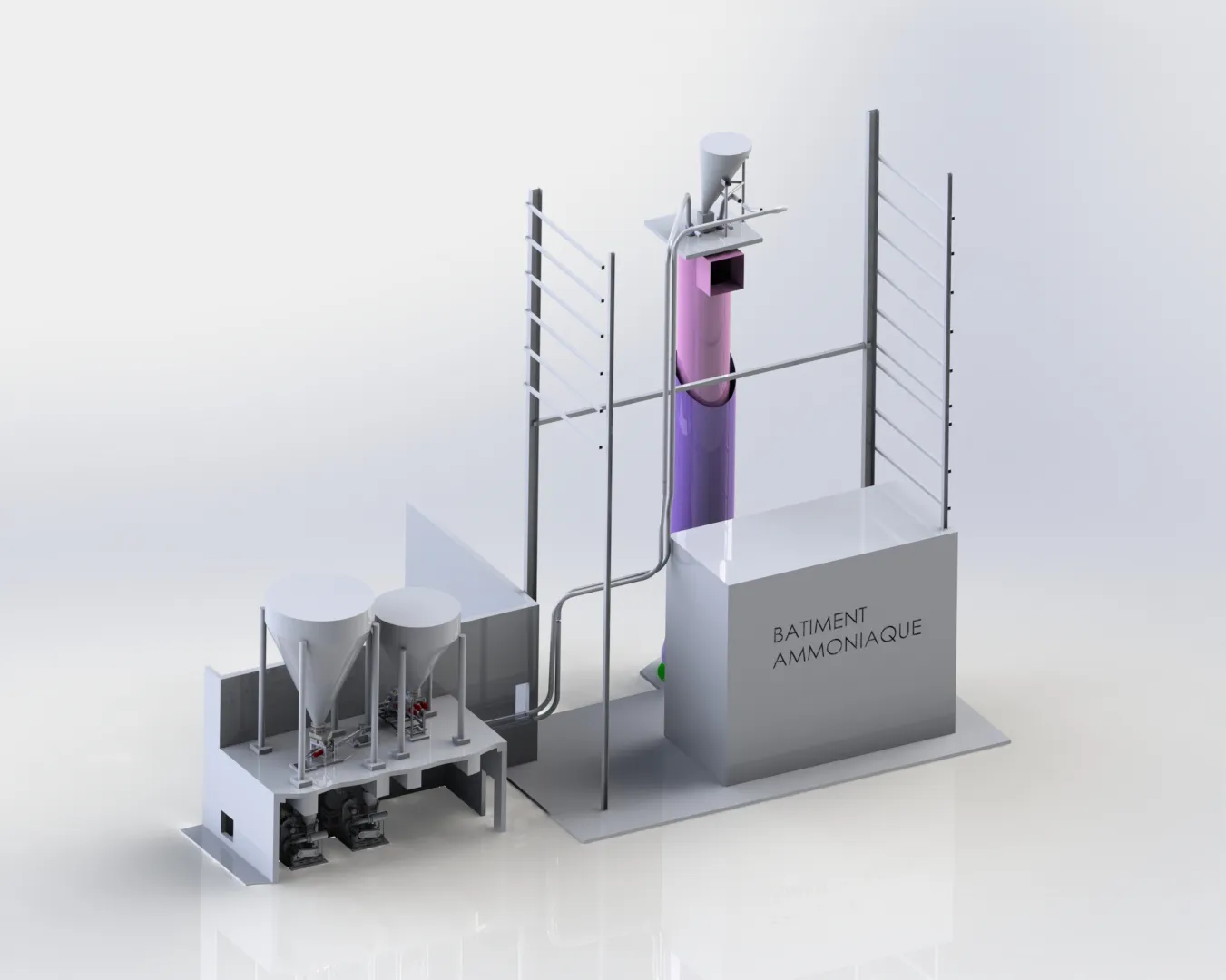

SITCOM COTE SUD DES LANDES

Product: Sodium bicarbonate

Issue: Smoke treatments with sodium bicarbonate to grind

Solution: Installation of an unblocker at the silo outlet (Silo not included in the scope of supply) with two transfer screws. At the screw outlet we have installed 2 grinders, which will reduce the granulometry of the bicarbonate and increase its efficiency close to the pollutants. Flow rate: 100 to 850 kg/h. Two stainless steel pipes for pneumatic transport and injection.

Applications: Incinerator Bénesse-Maremne

To discover more projects related to dry flue gas treatment, visit SCCM ALP.